Vertical Multi-Stage Centrifugal Pumps BL(T)

High-efficiency standard motor, Japan NSK bearings and cold-rolled 50ww800 silicon steel sheet made the pump high efficiency, low noise and maintenance-free. Totally enclosed shaft seal, IP55 protection grade, F class insulation grade, the special "double-lock" drive end bearing made the pump withstand higher inlet pressure.

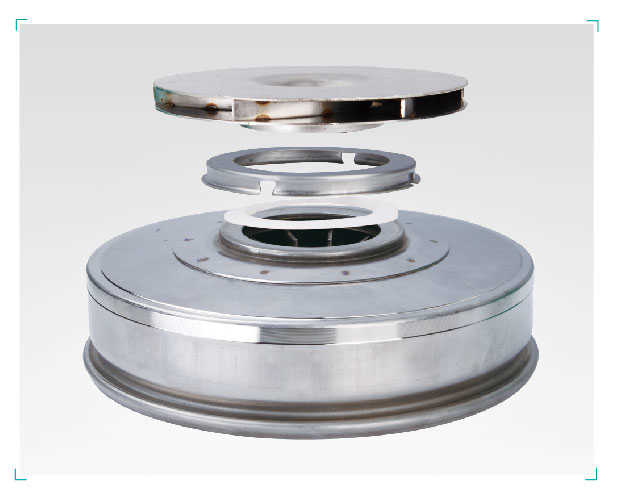

Balanced & container-type shaft seal with all the parts assembled together, no axial rotating to prevent the shaft and rubber parts from wearing, with the characteristics of rapid changing, easy installation and safe operation.Dynamic sealing is made of cemented carbide materials and the static sealing is fluorine rubber material which make the mechanical seal to be high temperature resistance, long service life, easy changing and other significant characteristics.

Being produced by the most advanced international laser welding technology,, no eliminate welding, ensure the high intensity and efficiency. The processing technology: precision casting, CNC lathe, CNC machining center, the modern advanced technology such as the laser welding technique and processing equipment.2T-4T is spot welding,16T and above is laser welding.

The built-in floating sealing ring of the pump cavity body could minimize the internal leakage produced by the differential pressure and prevent the energy consumption when liquid leaking back to the pump cavity body.

The pump core parts are designed to be multilevel interlocking, fastening nut locked, component system interlock assembly industry, to minimize the gap between the impeller per level, improve the efficiency of the impeller water conservancy, and ensure the stability, reliablity and efficiency of the pump core components.

Cold extrusion spline shaft with good surface quality, high machining accuracy, at the same time improve the comprehensive mechanical properties of the shaft and the reliability of the pump.

Model Instruction

Overview Of The Product

BL(T) series stainless steel multi-stage centrifugal pump (afterwards called pump)boasts characters of high efficiency,low noise, steady operation, etc.The pump set adopts the non-self-priming vertical multi-stage structure, which makes

a compact whole,its installation easy, its operation and maintenance convenient.

Application Limits

◎

Medium temperature: normal type:0℃ ~68℃ hot water type:68℃ ~120℃

◎

Ambient temperature:+40℃

◎

Advisable to use motor of higher power in case that the density or viscosity of medium is above that of water.

◎

pH: 5 to 8

Application Limits

Certificate

Electric Motor

◎

Full-enclosed and ventilating two-pole standard motor

◎

Protection class: IP55

◎

Insulation class: F

◎

Standard voltage Single phase 220V-50Hz Three phase:220/380V-50Hz

Energy Efficiency Standard (IEC60034-1)

Calculation Of minimum Inlet Pressure

If the pressure in pump is lower than the vapour pressure of medium, cavitation will occur, which will affect the performance of pump.

To avoid the cavitation and ensure the pump inlet has a minimum pressure, maximum suction head should be calculated as following:

Pb: Atmospheric pressure, bar (In close pipeline system, it can be considered as the system pressure );

NPSH: Net positive suction head, m (Value at maximum flow of Q-NPSH curve);

Hf: Suction pipe line loss (Value at maximum flow of corresponding pipeline);

Hv: Medium vapour pressure, m (Medium vapour pressure at corresponding temperature, the default medium is water, as shown in figure2 on the right );

Hs: Safety margin, m, general value is 0.5.

Calculation result: if H is positive, the pump is installed in suction way, otherwise, it is installed in downdraft way.

Note: It is not necessary to do above calculation under general conditions. Only when we use pump in the following situations do we

need to calculate the H:

Selection Of Pumps

Duty point of the pump:

From a duty point it is possible to select a pump on the basis of the curve charts shown in "performance curves/technical" data.

Dimensional data:

When sizing a pump the following must be taken into accounting:

Pump efficiency:

Before determining the best efficiency point, the operation pattern of the pump needs to be identified. If the pump expected to operate as the same duty point, then select a BL pump which is operating at a duty point corresponding with the best efficiency of the

pump.

As the pump is sized on the basis of the highest possible flow, it is important always to have the duty point to the right on the

efficiency curve(eta) in order to keep efficiency high when the flow drops

Pump material:

Selection of pump connection depend on

the rated pressure and pipe work. the pump offer a

wide range of texible connection such as:

Commonly used mechanical seal configuration tables

Maximum Work Pressure

Maximum Ambient Temperature

When the pump is operating in the place where ambient

temperature is higher than 40℃ or altitude is higher than

1000m,the output power of motor P2 will decrease because of poor

cooling caused by low air density.Therefore,in that case,the pump

should be equipped with high-power motor.

Performance Curve - BL(T)2

Performance Table

Dimensions

Performance Curve - BL(T) 4

Performance Table

Dimensions

Performance Curve - BL(T) 8

Performance Table

Dimensions

Performance Curve - BL(T) 12

Performance Table

Dimensions

Performance Curve - BL(T) 16

Performance Table

Dimensions

Performance Curve - BL(T) 20

Performance Table

Dimensions

Performance Curve - BL(T) 32

Performance Table

Dimensions

Performance Curve - BL(T) 45

Performance Table

Dimensions

Performance Curve - BL(T)64

Performance Table

Dimensions

Performance Curve - BL(T)90

Performance Table

Dimensions

Performance Curve - BL(T)120

Performance Table

Dimensions

Performance Curve - BL(T)150

Performance Table

Dimensions

Performance Curve - BL(T)200

Performance Table

Dimensions

Components & Materials

Components & Materials

>

>

Components & Materials

Packing Sizes & Weight

Packing Sizes & Weight

Packing Sizes & Weight

>

>

Hot Tags: Vertical Multi-Stage Centrifugal Pumps BL(T), China, Manufacturers, Suppliers, For Sale, Companies, Best, Price, Buy, High Quality

>

>

>

>

English

English  ελληνικά

ελληνικά  Esperanto

Esperanto  Afrikaans

Afrikaans  tiếng Việt

tiếng Việt  Català

Català  Italiano

Italiano  שפה עברית

שפה עברית  Cymraeg

Cymraeg  العربية

العربية  Gaeilge

Gaeilge  český

český  Eesti Keel

Eesti Keel  Galego

Galego  Indonesia

Indonesia  Español

Español  русский

русский  Nederlands

Nederlands  Português

Português  Norsk

Norsk  Türkçe

Türkçe  Lietuvos

Lietuvos  Latviešu

Latviešu  Pilipino

Pilipino  ภาษาไทย

ภาษาไทย  Română

Română  icelandic

icelandic  Polski

Polski  ייִדיש

ייִדיש  беларускі

беларускі  Français

Français  български

български  український

український  Hrvatski

Hrvatski  Deutsch

Deutsch  Kreyòl ayisyen

Kreyòl ayisyen  Dansk

Dansk  فارسی

فارسی  हिन्दी

हिन्दी  Suomi

Suomi  magyar

magyar  日本語

日本語  Srpski језик

Srpski језик  Shqiptar

Shqiptar  한국어

한국어  Svenska

Svenska  Македонски

Македонски  Slovenský jazyk

Slovenský jazyk  Malti

Malti  Malay

Malay  Slovenski

Slovenski  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Azərbaycan

Azərbaycan  Euskal

Euskal  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Қазақша

Қазақша  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  Latine

Latine  ລາວ

ລາວ  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  मराठी

मराठी  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  বাংলা ভাষার

বাংলা ভাষার  Burmese

Burmese  Hmong

Hmong  IsiXhosa

IsiXhosa  नेपाली

नेपाली  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  తెలుగు

తెలుగు  தமிழ்

தமிழ்  تمل

تمل  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Javanese

Javanese  Yoruba

Yoruba