Vertical Multi Stage Centrifugal Pumps BLT

We're known as one of the most professional Vertical Multi-Stage Centrifugal Pumps manufacturers and suppliers in China for our quality products and customized service. Please rest assured to buy bulk Vertical Multi-Stage Centrifugal Pumps at low price here or contact our factory for free sample and pricelist.

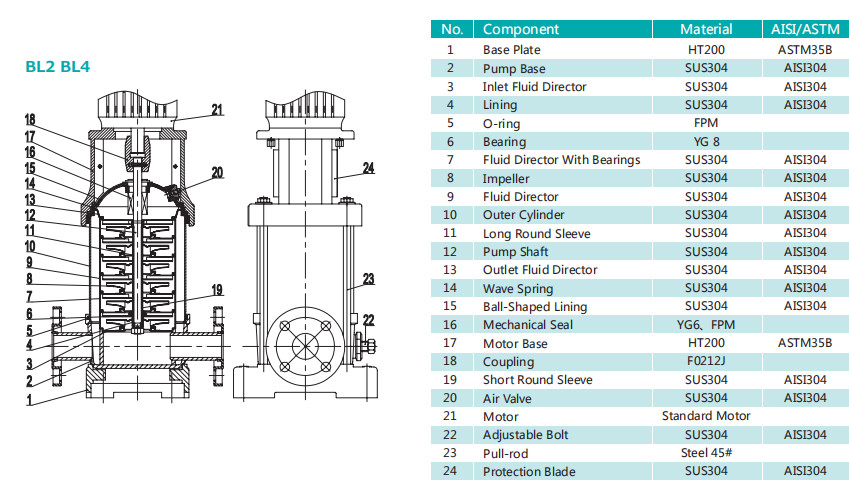

BL(T) series stainless steel multi-stage centrifugal pump (afterwards called pump)boasts characters of high efficiency, low noise, steady operation, etc.The pump set adopts the non-self-priming vertical multi-stage structure, which makes a compact whole,its installation easy, its operation and maintenance convenient.

|

Water supply |

BL |

BLT |

|

Filtration and transfer at waterworks |

● |

● |

|

Distribution from waterworks |

● |

● |

|

Pressureboosting in mains |

● |

● |

|

Pressure boosting in high-rise buildins,hotels,etc. |

● |

● |

|

Pressure boosting for industrial water supply |

● |

● |

|

Industry |

|

|

|

Pressure boosting |

|

|

|

Process water systems |

● |

● |

|

Washing and cleaning systems |

● |

● |

|

Vehicle washing tunnels |

● |

● |

|

Fire fighting systems |

● |

● |

|

Liquid transfer |

|

|

|

Cooling and air-conditioning systems(refrigerants) |

● |

● |

|

Boiler feed and condensate systems |

● |

● |

|

Machine tools(cooling lubricants) |

● |

● |

|

Aquafarming |

● |

● |

|

Transfer |

|

|

|

Oil and alcohol |

● |

● |

|

Glycol and coolants |

● |

● |

|

Water treatment |

|

|

|

Ultra-filtration systems |

● |

○ |

|

Reverse osmosis systems |

● |

○ |

|

Softening, ionising, demineralizing systems |

● |

○ |

|

Distillation sys tems |

● |

○ |

|

Separators |

● |

○ |

|

Swimming baths |

● |

● |

|

lrrigation |

|

|

|

Field irrigation(flooding) |

● |

● |

|

Sprinkler irrigation |

● |

● |

|

Drip-feed irrigation |

● |

● |

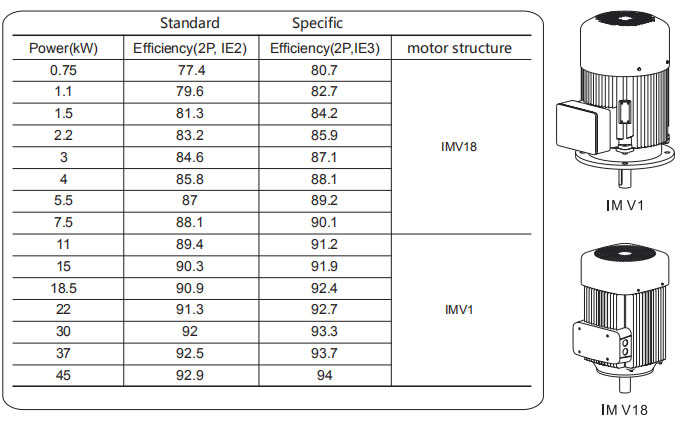

Energy Efficiency Standard (IEC60034)

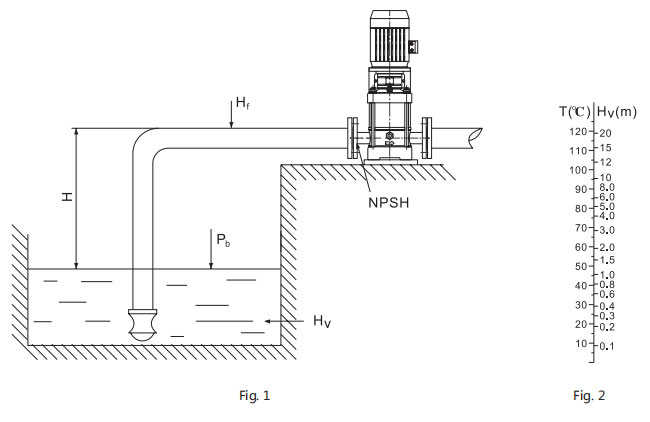

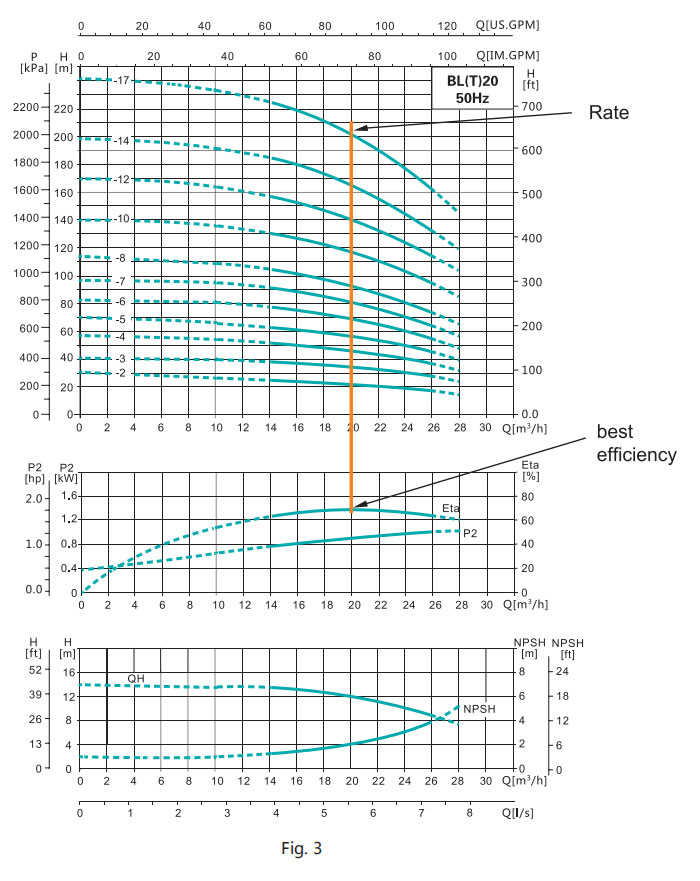

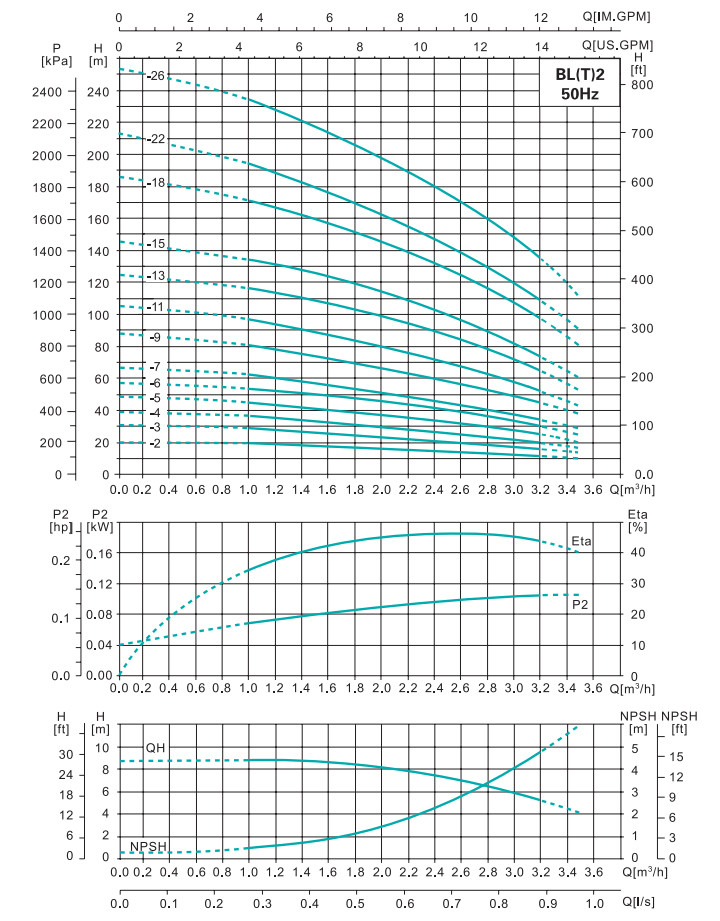

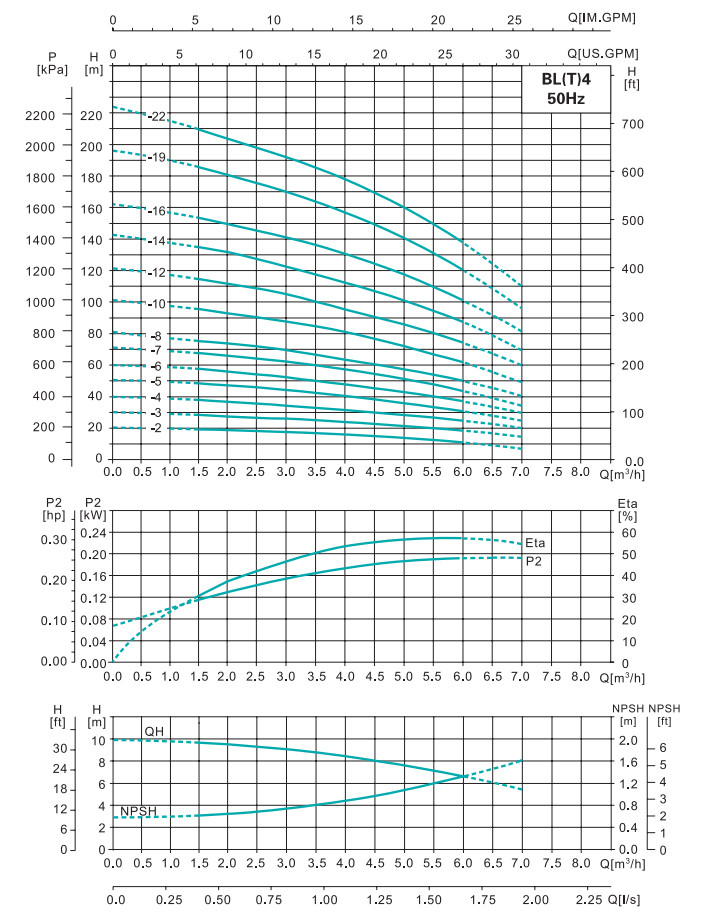

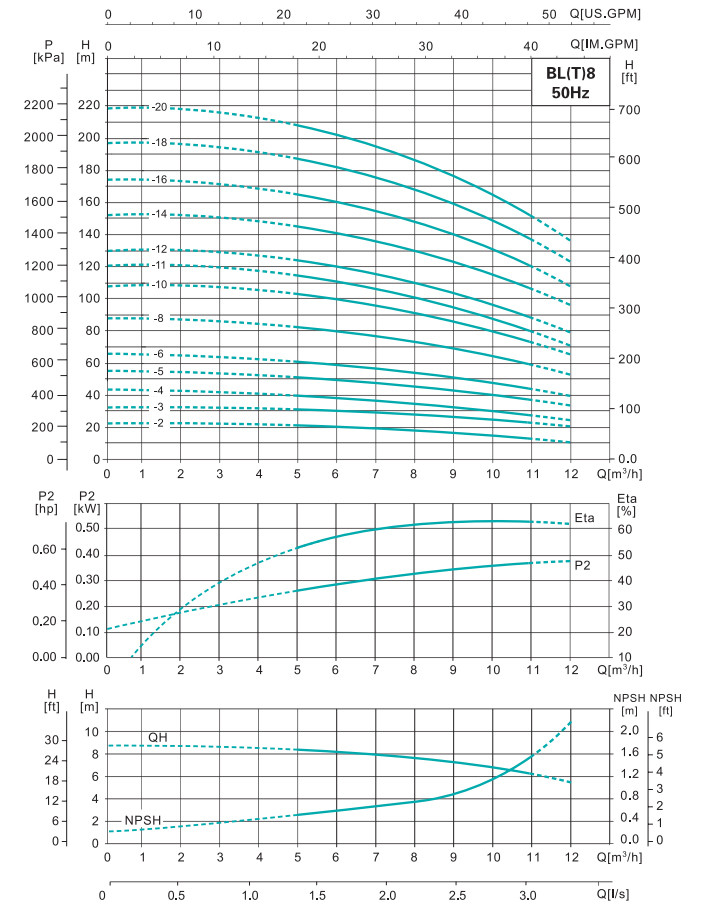

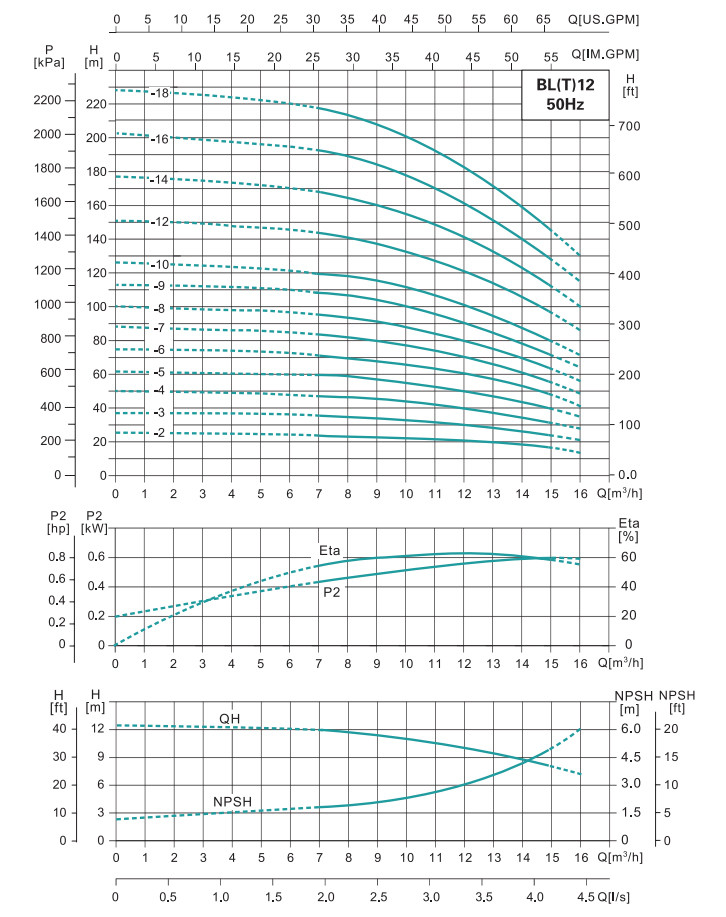

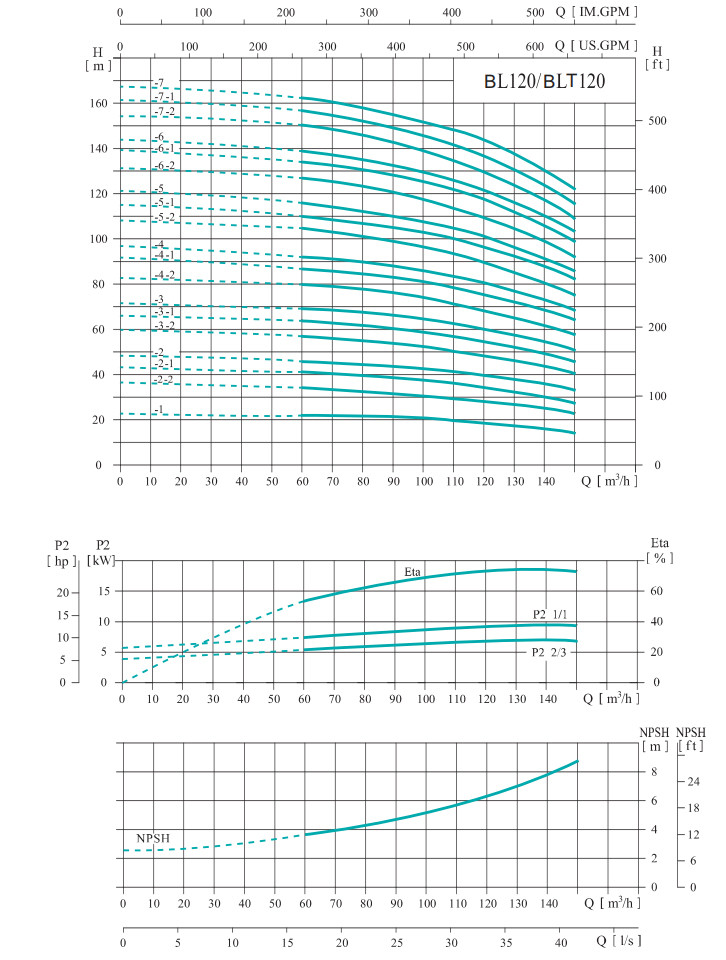

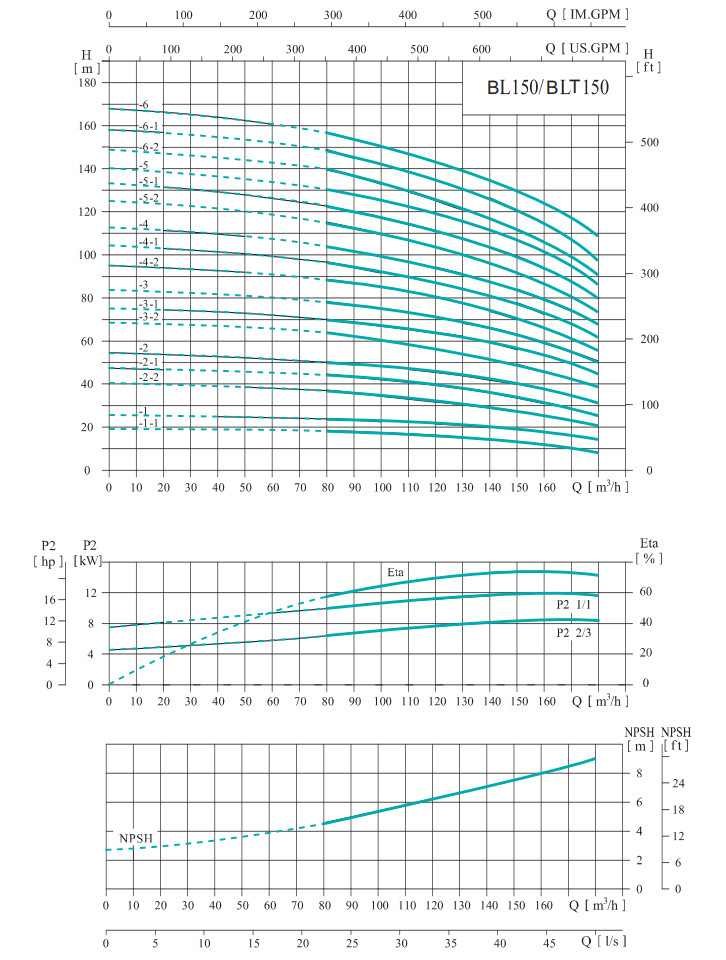

Calculation Of minimum Inlet Pressure

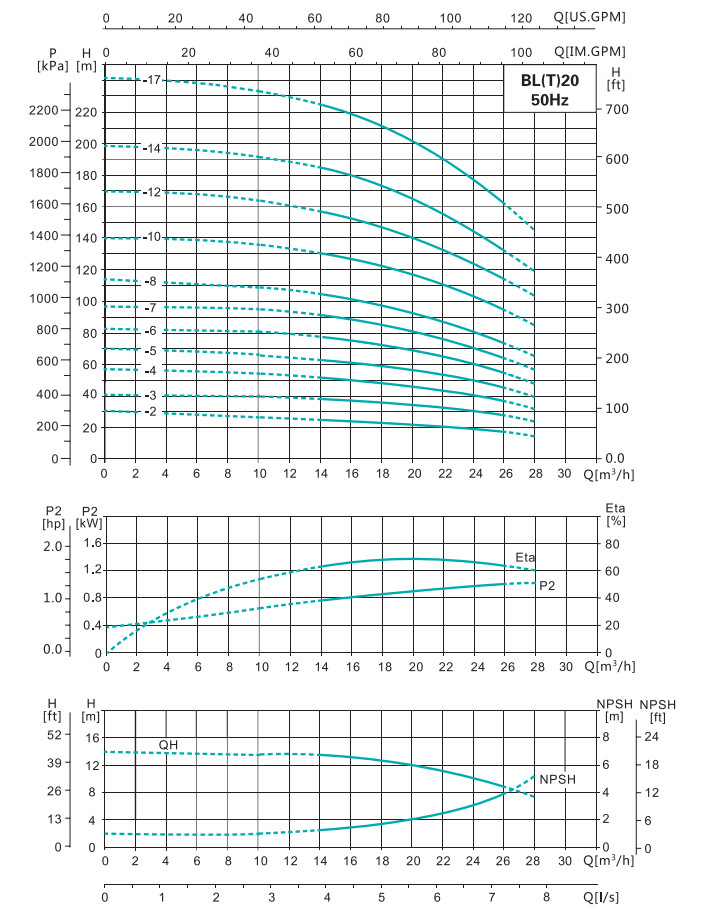

If the pressure in pump is lower than the vapour pressure of medium, cavitation will occur, which will affect the performance of pump. To avoid the cavitation and ensure the pump inlet has a minimum pressure, maximum suction head should be calculated as following:

H=Pbx10.2-NPSH-Hf-hv-Hs

Pb: Atmospheric pressure, bar (In close pipeline system, it can be considered as the system pressure );

NPSH: Net positive suction head, m (Value at maximum flow of Q-NPSH curve);

Hf: Suction pipe line loss (Value at maximum flow of corresponding pipeline);

Hv: Medium vapour pressure, m (Medium vapour pressure at corresponding temperature, the default medium is water, as shown in figure4 on the right );

Hs: Safety margin, m, general value is 0.5.

Calculation result: if H is positive, the pump is installed in suction way, otherwise, it is installed in downdraft way.

Note: It is not necessary to do above calculation under general conditions. Only when we use pump in the following situations do we need to calculate the H:

1. Medium temperature is high;

2.The velocity of flow is larger than rated value;

3.Suction head is big or inlet pipeline is long;

4.System pressure is small;

5.Inlet condition is bad.

Selection Of Pumps

Selection of pumps should be based on:

Duty point of the pump.

Dimensional data such as pressure loss as aresult of height differences,friction loss in the pipework,

Pump efficiency etc.

Pump materials

Pump connections

Commonly used mechanical seal configuration tables

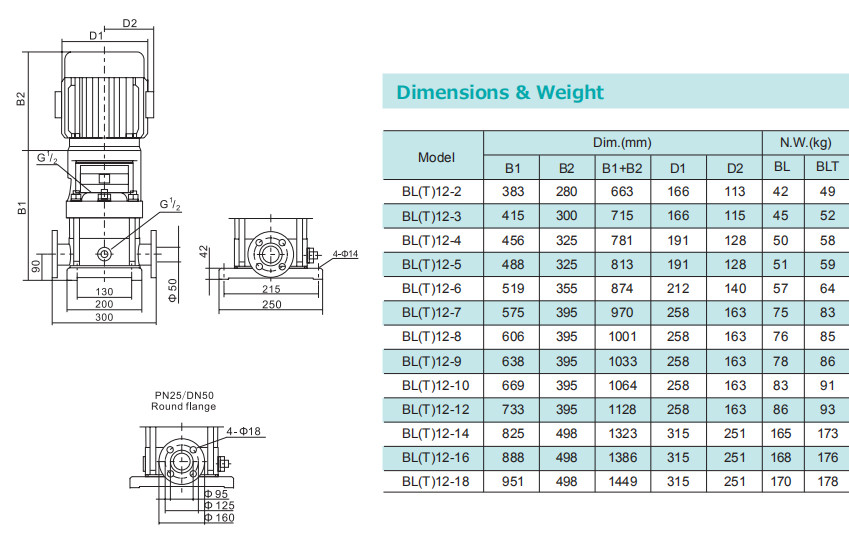

1. Duty point of the pump:

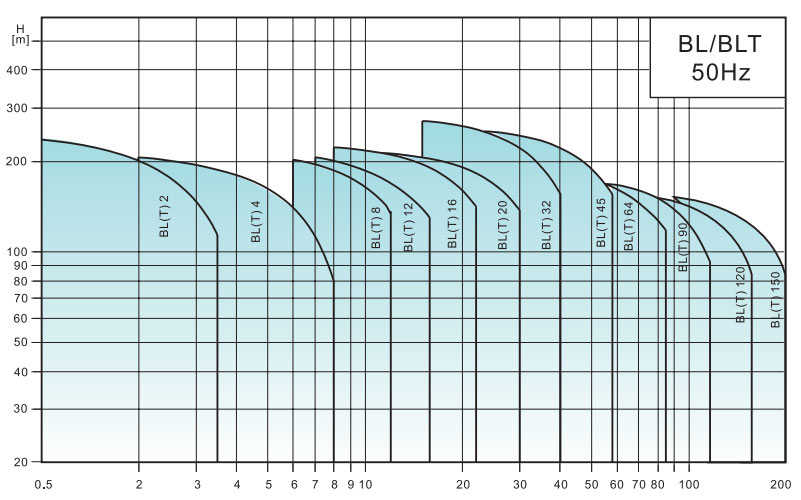

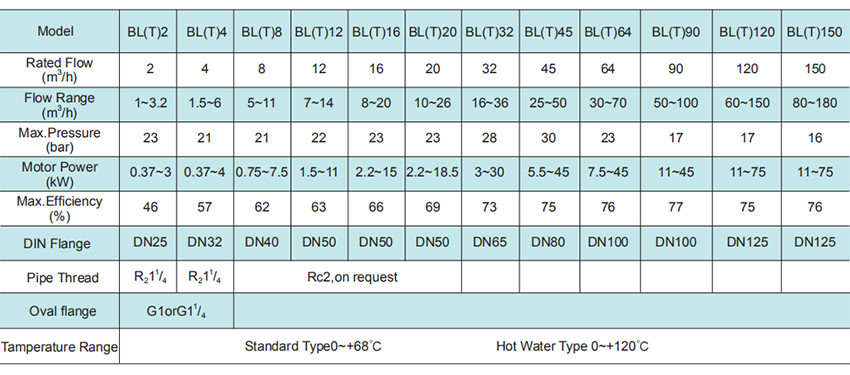

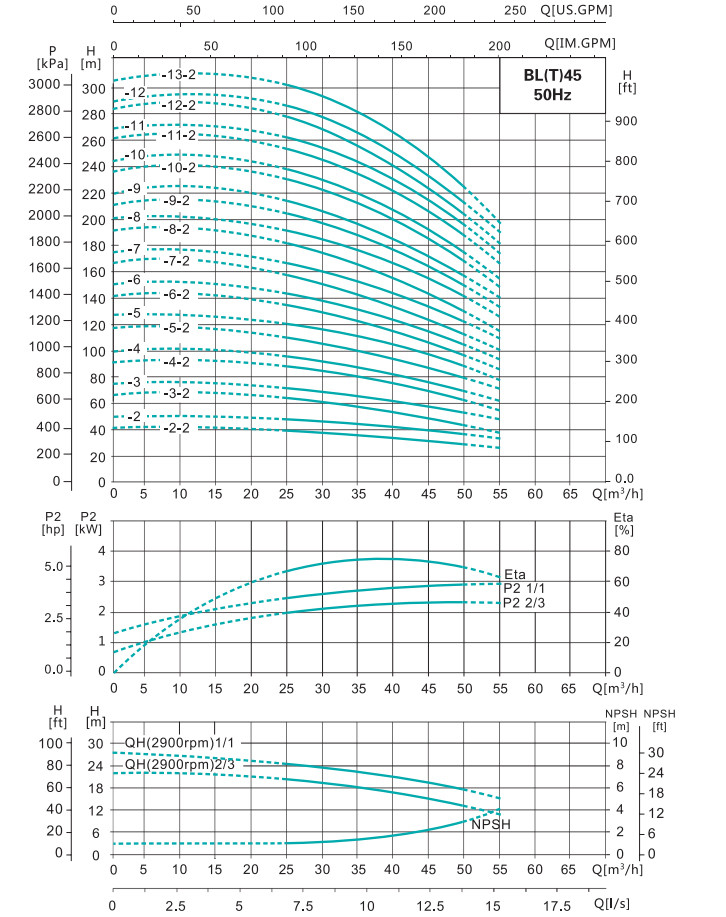

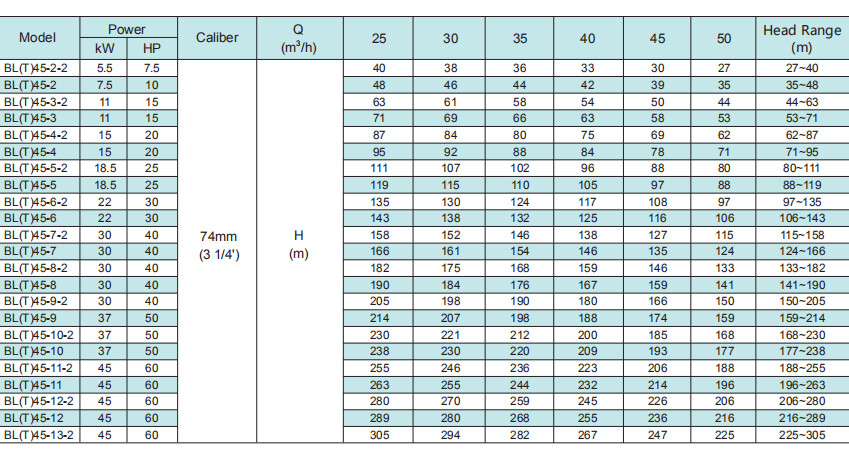

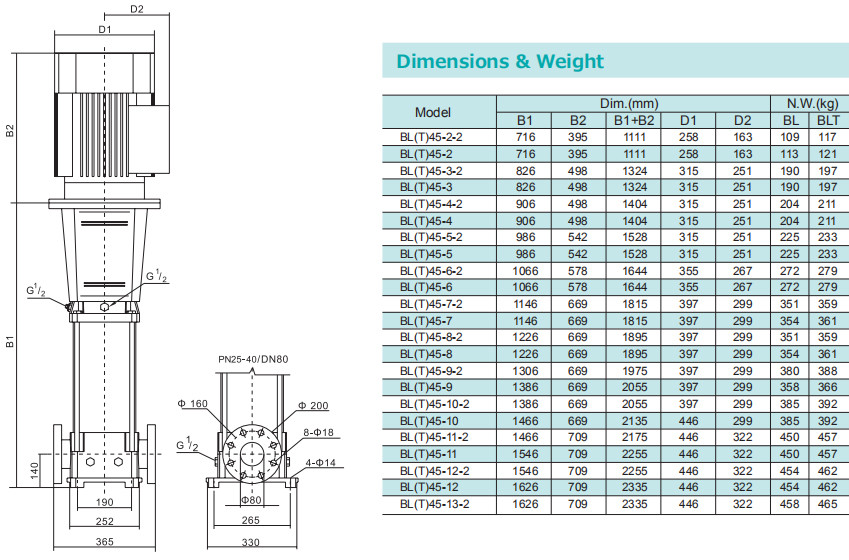

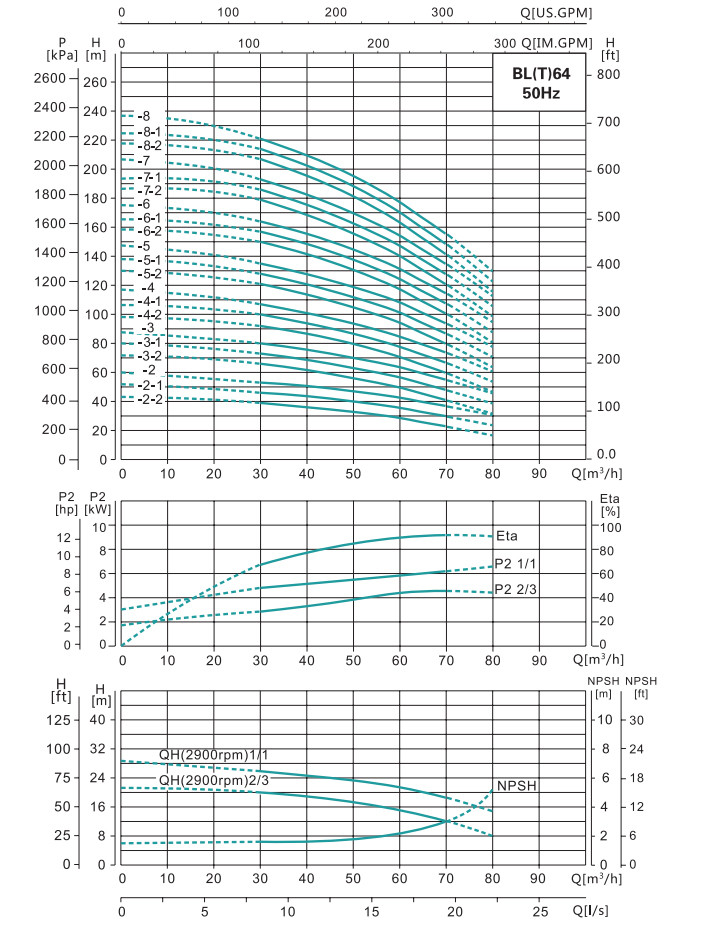

From a duty point it is possible to select a pump on the basis of the curve charts shown in "performance curves/technical" data.2. Dimensional data:

When sizing a pump the following must be taken into accounting: •Required flow and pressure at the draw-off point. •Pressure loss as a result of height differences. •Friction loss in the pipework(Hf) (Refer to Fig.1) It may. •Best efficiency at the estimated duty point. •NPSH value. •For calculation of the NPSH value, see corresponding curves chart.3. Pump efficiency:

Before determining the best efficiency point, the operation pattern of the pump needs to be identified. If the pump expected to operate as the same duty point, then select a BL pump which is operating at a duty point corresponding with the best efficiency of the pump.As the pump is sized on the basis of the highest possible flow, it is important always to have the duty point to the right on the efficiency curve(eta) in order to keep efficiency high when the flow drops.

4. Pump material:

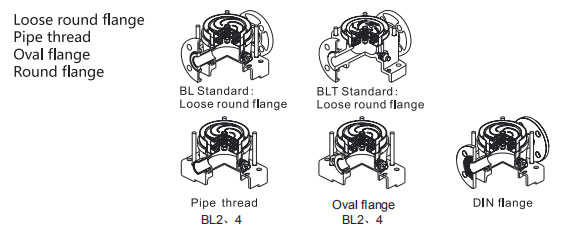

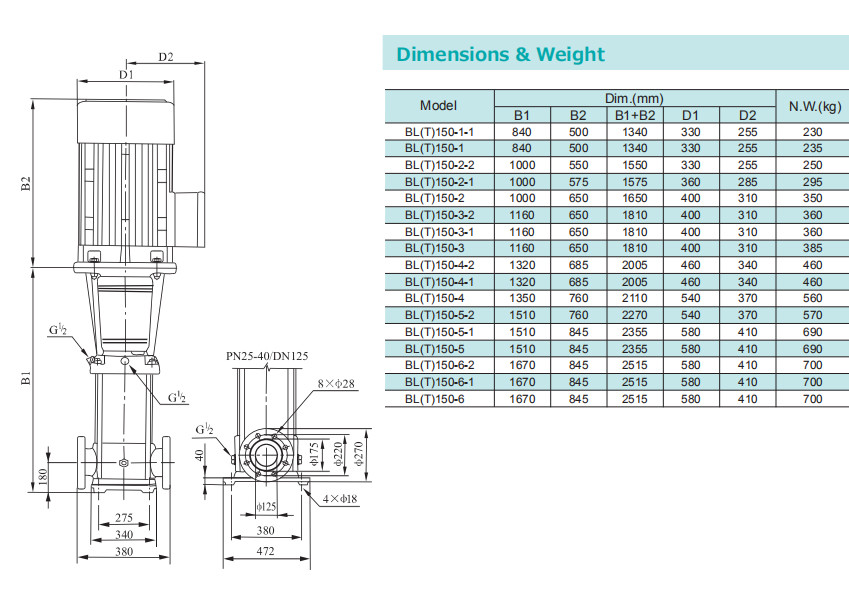

Selection of pump connection depend on the rated pressure and pipe work. the pump offer a wide range of ftexible connection such as:

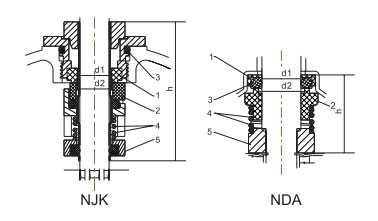

5. Commonly used mechanical seal configuration tables

| Application Field | Shaft seal type | Shaft seal material | ||||||||||

| Normal | Special | 1 | 2 | 3 |

4

5

|

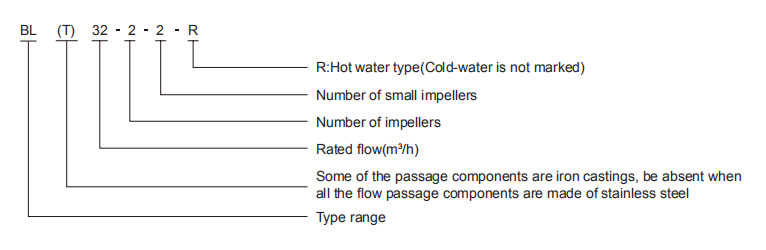

Type key | ||||||

| Rotating part | Code | Stationary part | Code | Elastomers | Code | Compression spring | Collor | Code | ||||

| 0℃ to +90℃ clean water | ● | Graphite | A | SiC | S | FPM | F | SUS304 | C | ASFC | ||

| 0℃ to +90℃ clean water | ● | WC | W | Graphite | A | FPM | F | SUS304 | C | WAFC | ||

| +90℃ to +120℃ corrosion resistance | ● | SiC | S | SiC | S | EPDM | E | SUS304 | C | SSEC | ||

| up to 0℃ | ● | WC | W | WC | W | EPDM | E | SUS304 | C | WWEC | ||

| Mechanical seal type | Pump model | d1 | d2 | h |

| NJK | BL(T)2/4 | 12 | 12 | 55 |

| BL(T)8/12/16/20 | 16 | 16 | 57.5 | |

| BL(T)32/45/60/90 | 22 | 22 | 72 | |

| NDA | BW(J)2/4 | 12.7 | 16 | 32 |

| BW(J)8/16 | 17.4 | 20 | 33.5 |

|

Model |

Curve No. |

|

BL(T)2,4 |

2 |

|

BL(T)8,12,16,20 |

3 |

|

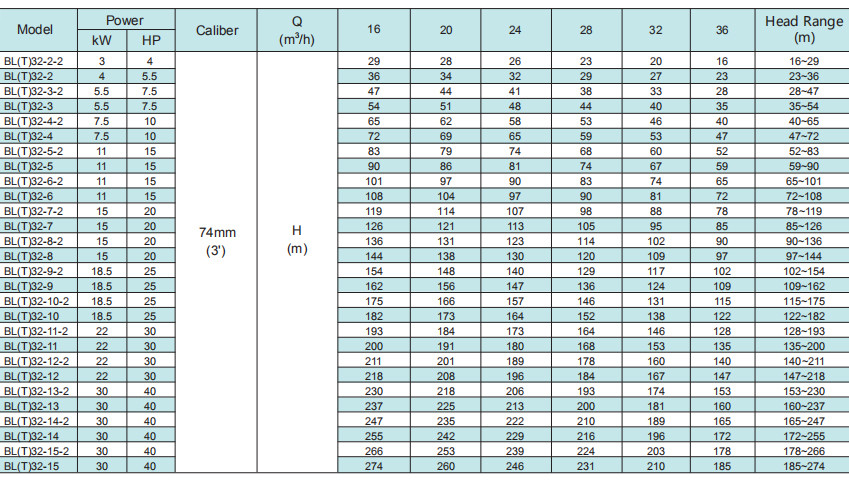

BL(T)32-2-2~BL(T)32-7 |

1 |

|

BL(T)32-8-2~BL(T)32-12 |

4 |

|

BL(T)32-13~BL(T)32-15-2 |

5 |

|

BL(T)45-2-2~BL(T)45-6 |

1 |

|

BL(T)45-7-2~BL(T)45-9 |

4 |

|

BL(T)45-10-2~BL(T)45-13-2 |

5 |

|

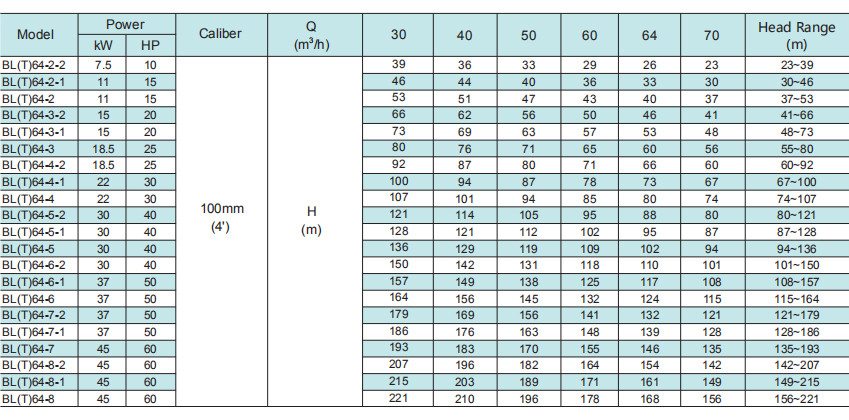

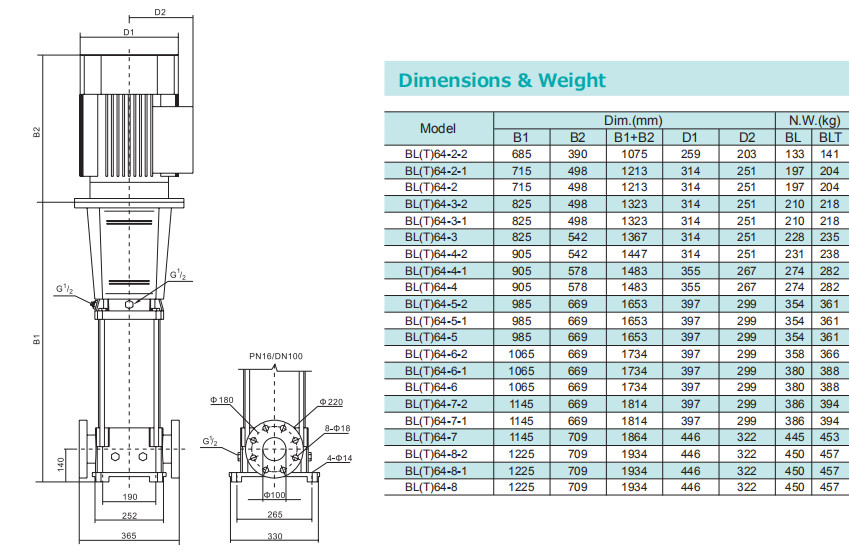

BL(T)64-2-2~BL(T)64-5-2 |

1 |

|

BL(T)64-5-1~BL(T)64-8 |

4 |

|

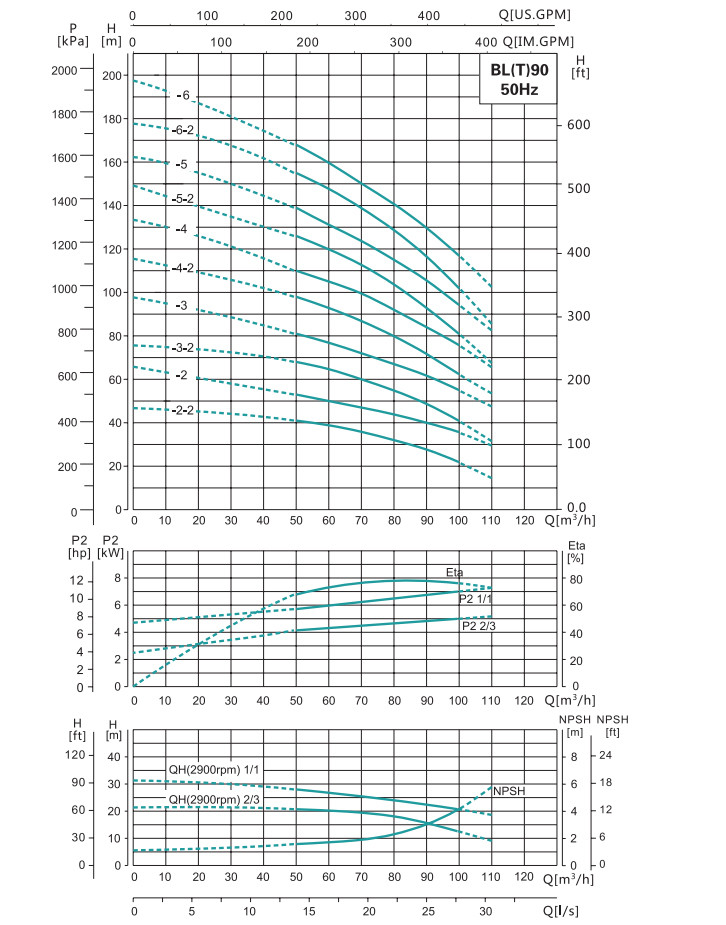

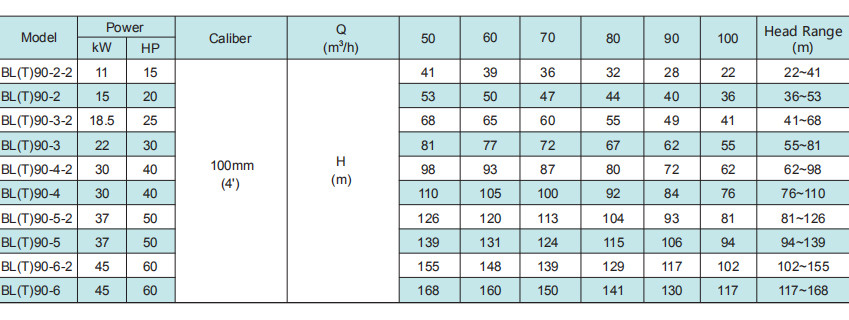

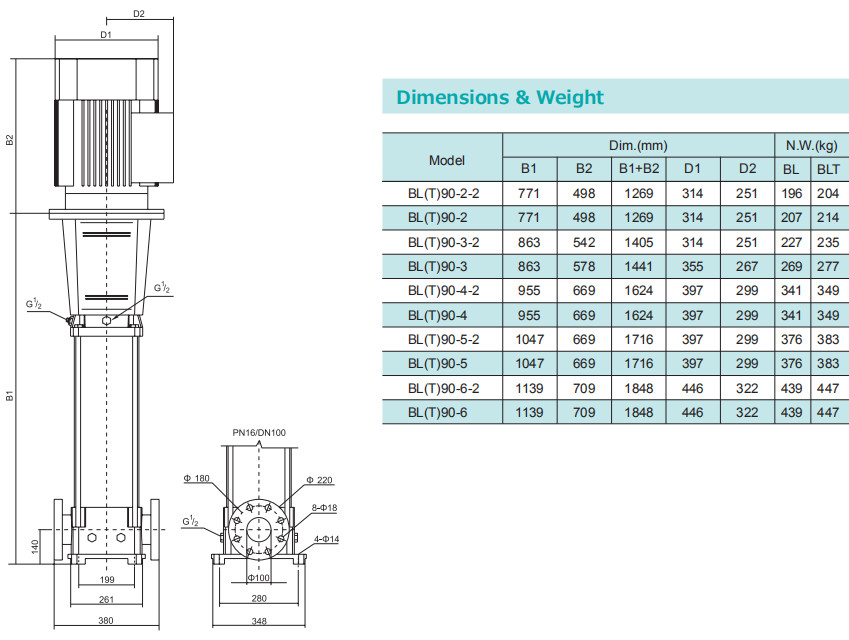

BL(T)90-2-2~BL(T)90-4-2 |

1 |

|

BL(T)90-4~BL(T)90-6 |

4 |

|

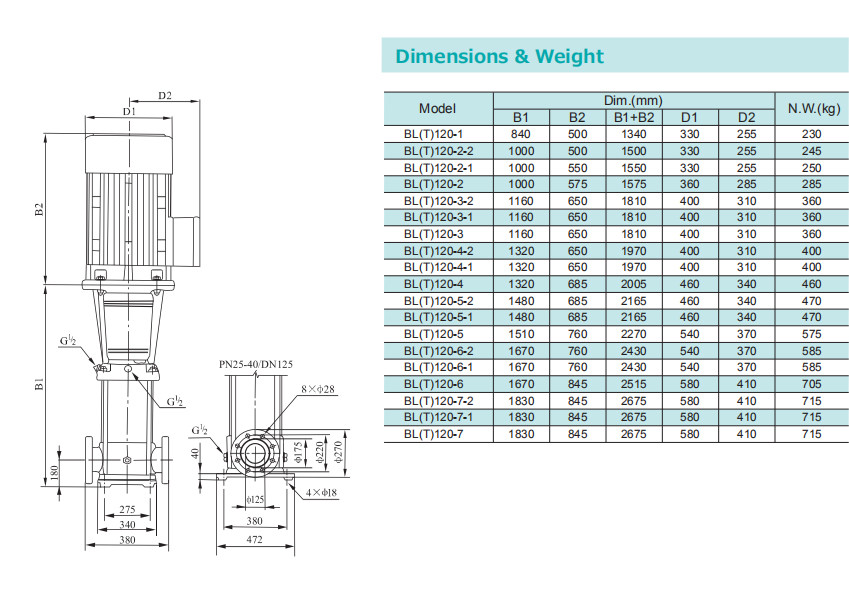

BL(T)120,150 |

6 |

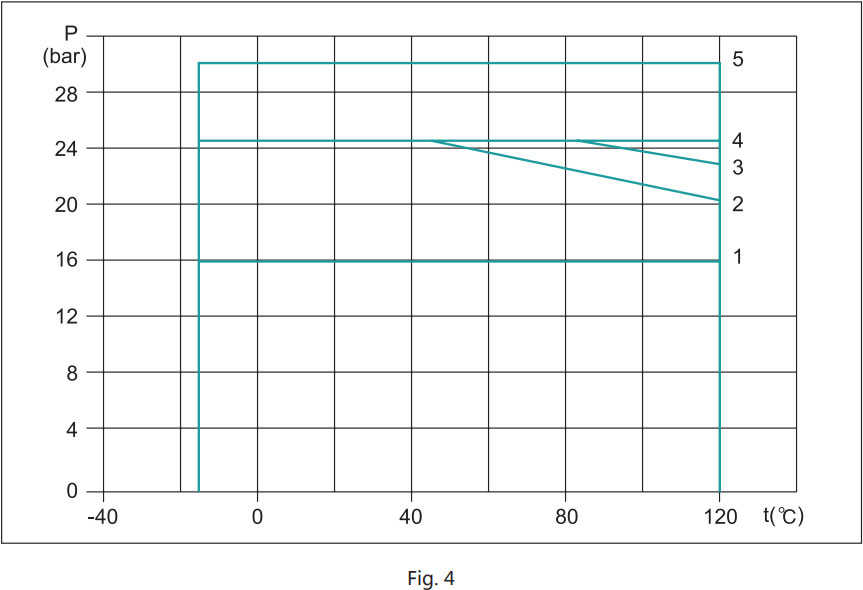

The limits of pressure and temperature are shown in the following fig.4,the pressure and temperature must be in the shown in the fig. 4.

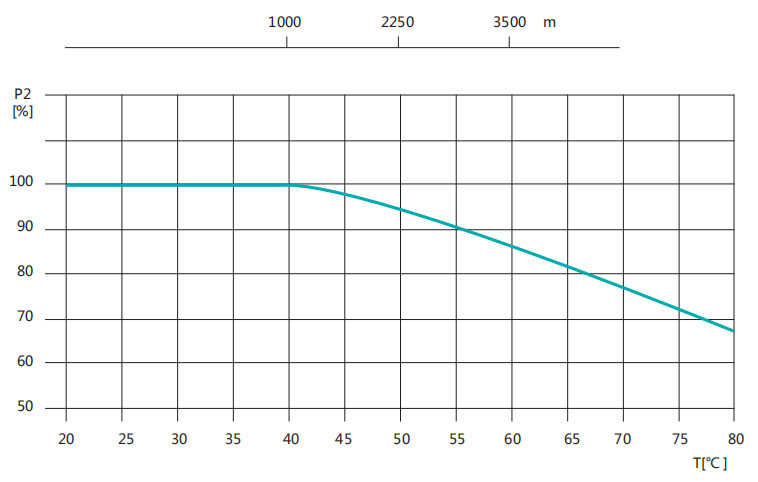

When the pump is operating in the place where ambient temperature is higher than 40℃ or altitude is higher than 1000m,the output power of motor P2 will decrease because of poor cooling caused by low air density.Therefore, in that case,the pump should be equipped with high-power motor.

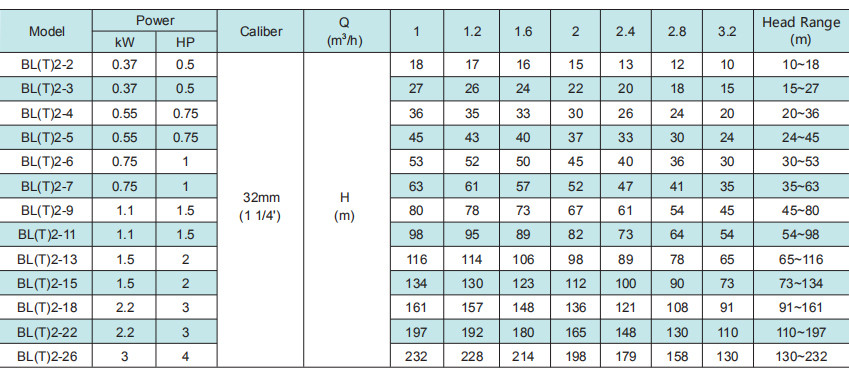

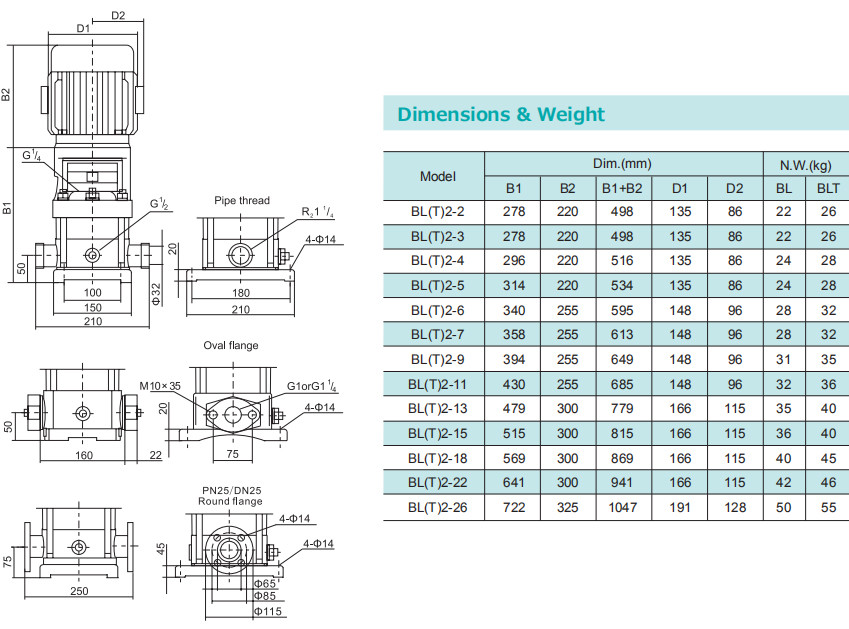

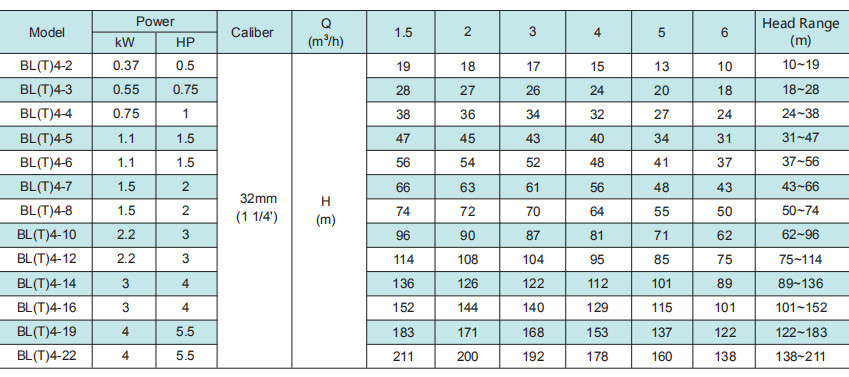

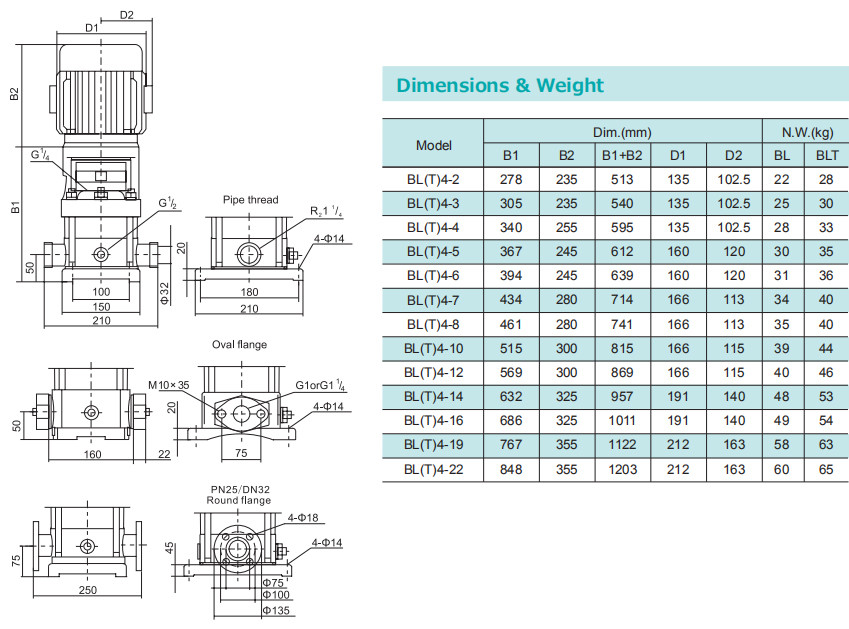

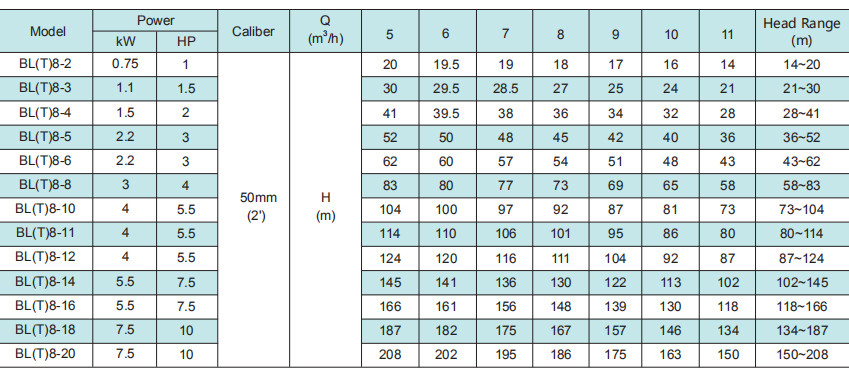

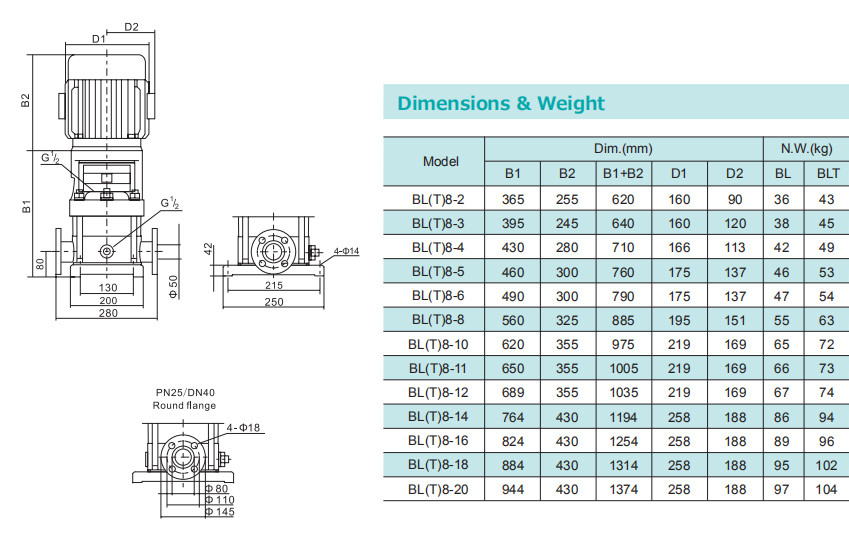

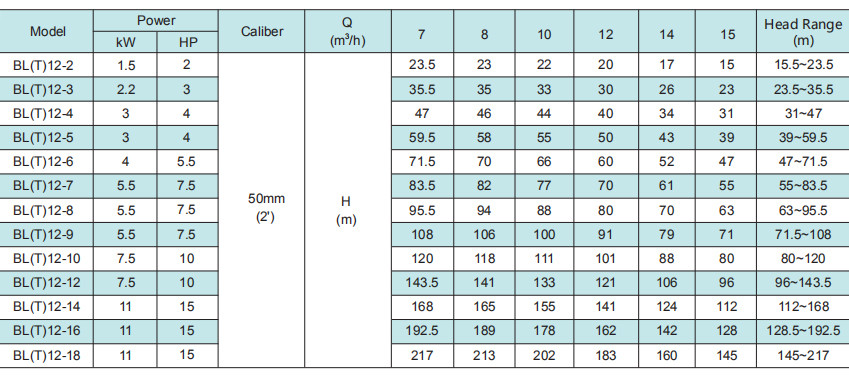

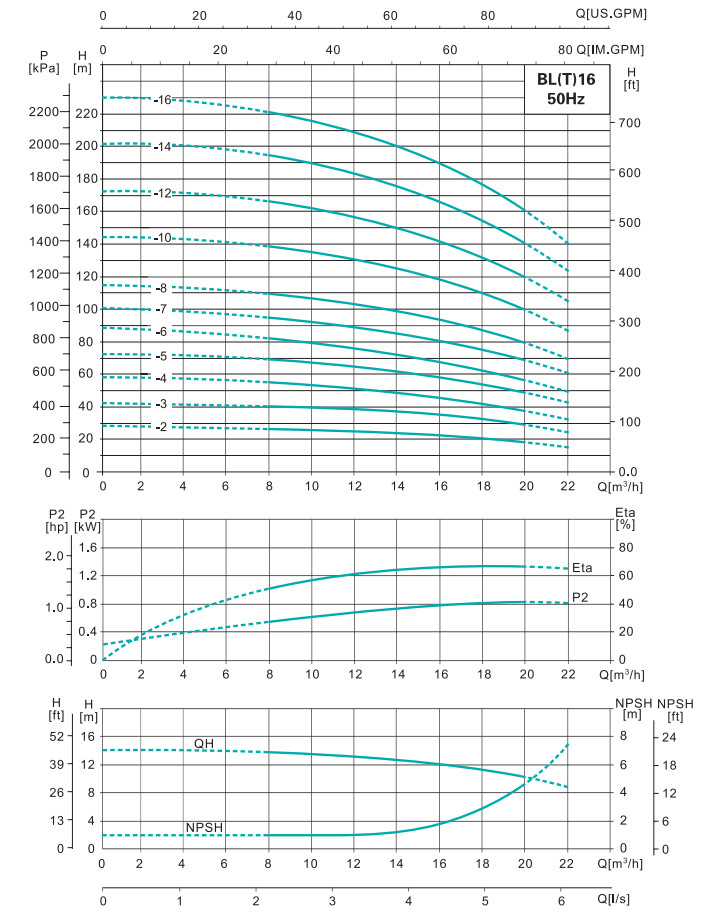

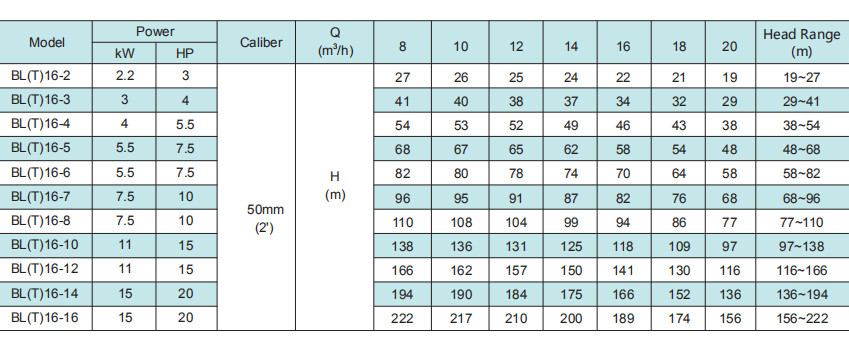

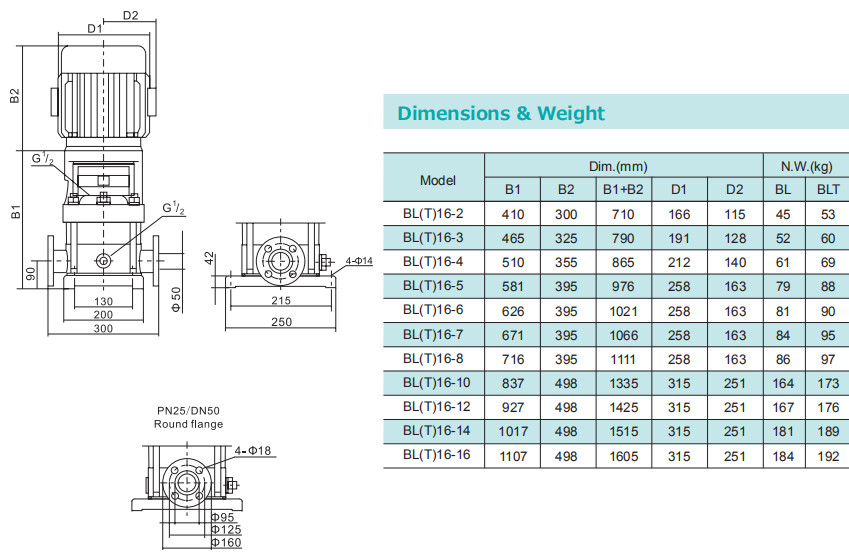

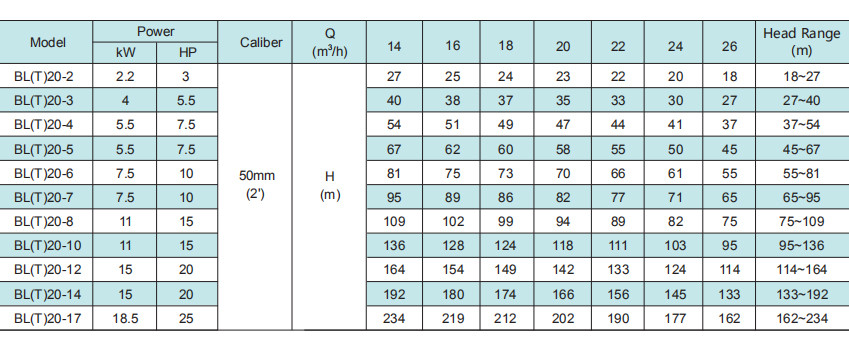

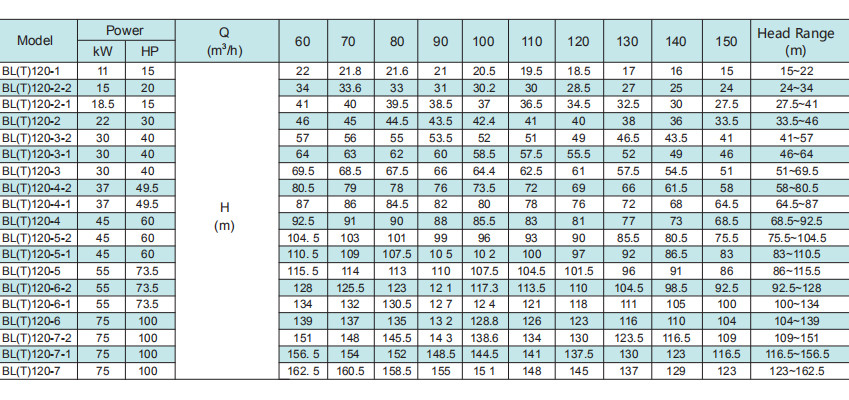

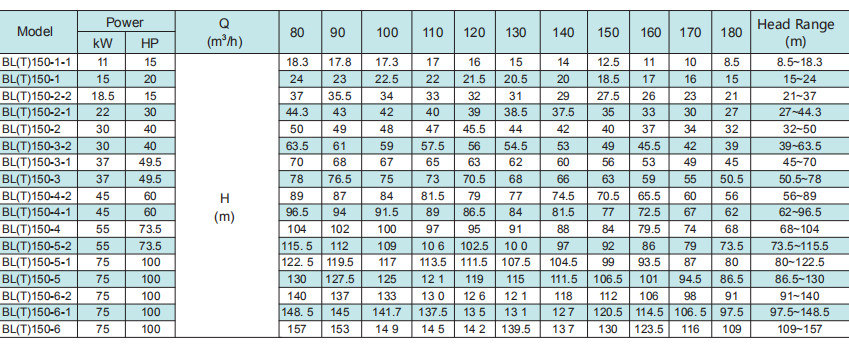

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

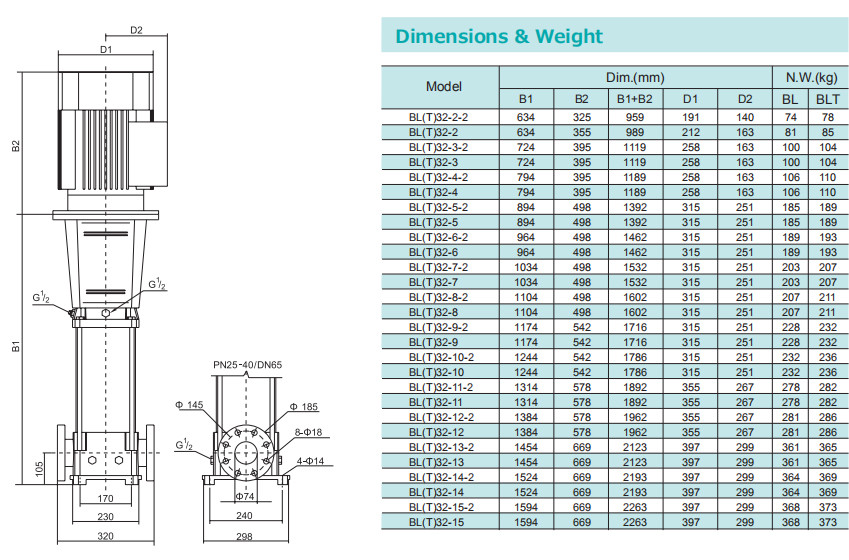

PN25-40/DN100 standard flange, on request.

It is recommended to be used within lift range.

PN25-40/DN100 standard flange, on request.

It is recommended to be used within lift range.

It is recommended to be used within lift range.

English

English  ελληνικά

ελληνικά  Esperanto

Esperanto  Afrikaans

Afrikaans  tiếng Việt

tiếng Việt  Català

Català  Italiano

Italiano  שפה עברית

שפה עברית  Cymraeg

Cymraeg  العربية

العربية  Gaeilge

Gaeilge  český

český  Eesti Keel

Eesti Keel  Galego

Galego  Indonesia

Indonesia  Español

Español  русский

русский  Nederlands

Nederlands  Português

Português  Norsk

Norsk  Türkçe

Türkçe  Lietuvos

Lietuvos  Latviešu

Latviešu  Pilipino

Pilipino  ภาษาไทย

ภาษาไทย  Română

Română  icelandic

icelandic  Polski

Polski  ייִדיש

ייִדיש  беларускі

беларускі  Français

Français  български

български  український

український  Hrvatski

Hrvatski  Deutsch

Deutsch  Kreyòl ayisyen

Kreyòl ayisyen  Dansk

Dansk  فارسی

فارسی  हिन्दी

हिन्दी  Suomi

Suomi  magyar

magyar  日本語

日本語  Srpski језик

Srpski језик  Shqiptar

Shqiptar  한국어

한국어  Svenska

Svenska  Македонски

Македонски  Slovenský jazyk

Slovenský jazyk  Malti

Malti  Malay

Malay  Slovenski

Slovenski  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Azərbaycan

Azərbaycan  Euskal

Euskal  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Қазақша

Қазақша  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  Latine

Latine  ລາວ

ລາວ  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  मराठी

मराठी  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  বাংলা ভাষার

বাংলা ভাষার  Burmese

Burmese  Hmong

Hmong  IsiXhosa

IsiXhosa  नेपाली

नेपाली  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  తెలుగు

తెలుగు  தமிழ்

தமிழ்  تمل

تمل  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Javanese

Javanese  Yoruba

Yoruba